News & Updates

Each drop counts: dose monitoring to prevent overdose

- Writerkrissadmin

- Date2019-09-05 00:00

- Hits12206

- flowmeter that accurately measures microscopic doses -

# According to the U.S. Food and Drug Administration (FDA) 56,000 medical accidents were caused by infusion pump errors from 2005 to 2009, with 500 of those cases leading to death. This was because patients were administered the wrong doses by device error or human error on the part of medical professionals. Korean hospitals also rely on infusion pump settings, while the management system remains inadequate. This makes it difficult to eradicate dose-related accidents.

Technology to measure microscopic doses administered at a rate slower than a drop a minute in real time has been developed at the Korea Research Institute of Standards and Science.

Senior research scientist Dr. Seok Hwan Lee and his team at KRISS Center for Thermometry and Fluid flow Metrology have developed a flowmeter that can accurately measure microscopic doses as small as 2 mL per hour. Considering that a drop of water is about 0.05 mL, 2 mL per hour is about 0.03 mL or less than a drop per minute.

Using this technology, the dose being administered can be monitored in real time, to prevent medical accidents such as overdosing. Furthermore, the flowmeter works with a clamp-on mechanism resembling a clothespin, allowing convenient contactless measurement that was not available in existing methods.

The administration of medication in accurate doses is the most basic component of medical practice. When medication is injected into infants, or when administering special medications such as painkillers or anesthetics, even a few mL over the specified dose can be lethal. However, due to the large number of patients in the actual clinical setting, medical professionals usually cannot monitor the dose being administered in real time, only controlling the initial settings for infusion pumps.

The problem is that the medication administration rate can deviate significantly from the set value. This is why it often feels like the injection speed of an IC drip accelerates at certain moments, and then slows down the next. The main causes of dosing issues are mechanical errors and malfunctions, which become more frequent the longer the infusion pump is used.

However, there was no way to check if the flow rate of the infusion pump matches the set value. Contactless methods using ultrasound cannot be used to measure microscopic doses. Thus, the only method has been to cut the tubing of the infusion pump to install a flowmeter, which involves direct contact, exposing the drug to contamination. It was also very costly, making it almost impossible to use in actual clinical practice.

Dr. Seok Hwan Lee’s team at KRISS came up with a perfect solution for the above issues by developing an infrared absorption-based thermal mass flowmeter. With this technology, flow rates as slow as 2 mL/h can be measured without damaging the pump in any way. The flowmeter works with a clamp-on mechanism, which measures the flow when the infusion pump tubing is clamped from the outside.

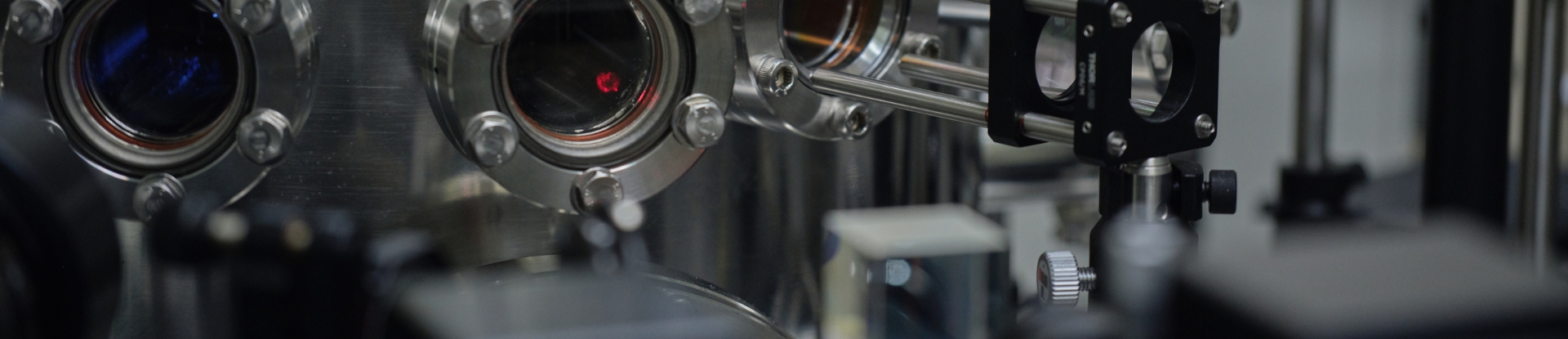

The key to this flow measurement technology lies in the temperature. When there is a heat source inside the tube, the heat is transferred together with the flow. By measuring this transfer of heat the flow can be quantified accurately. With this, the team utilized the phenomenon in which the infrared absorption of water changes according to temperature at a specific wavelength. Thus, they heated a spot in the liquid using a laser with a wavelength of 1450 nm, and then measured the temperature difference between upstream and downstream to measure the flow without contact.

“If we monitor drug doses in real time using this technology, we will be able to greatly reduce medical accidents of overdosing caused by mechanical errors or mistakes by medical professionals,” Dr. Seok Hwan Lee explains, adding, “the technology has great potential for widespread commercialization as it can be used in the simultaneous administration of different drugs, and can be miniaturized and produced at a low cost.”

This study was sponsored by KRISS Key Projects, the European Association of National Metrology Institute (EURAMET), and the National Research Foundation of Korea. It was published in Metrologia (IF: 3.447), a leading journal in the field of metrology in July. This result is part of a project that has received funding from the EMPIR programme co-financed by the Participating States and from the European Union’s Horizon 2020 research and innovation programme.

○ Detailed description of technology

? Infrared absorption method

The infrared absorption method obtains material properties such as temperature and density by passing infrared light through an object and measuring the absorption rate. In this study, the light absorbed in water was used to measure the temperature of water. As the infrared absorption of water changes according to temperature at the wavelength spectrum of 1550 nm to 1650 nm, the temperature of the water in the tube could be measured without contact.

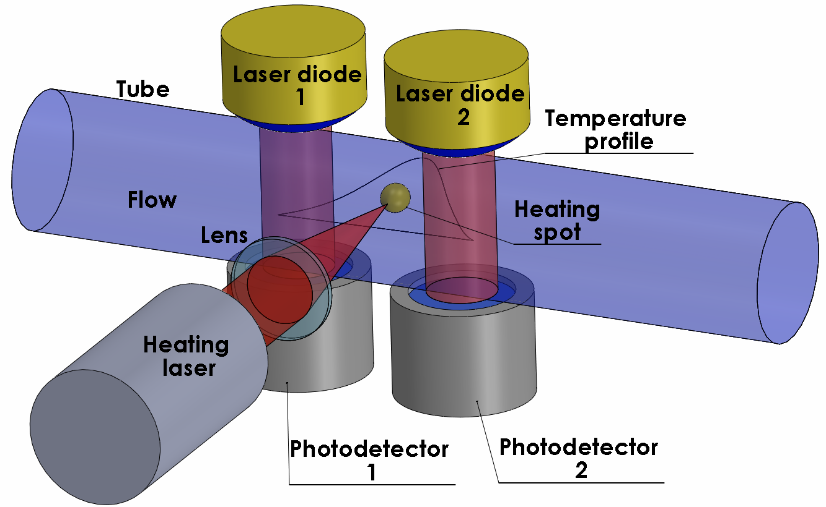

? Thermal mass flowmeter

The thermal mass flowmeter measures flow by heating a fluid in one spot and measuring the difference in temperatures upstream and downstream from the heated spot. In this study, a contactless thermal mass flowmeter was developed to address issues in conventional thermal mass flowmeter.

▲ Mimetic diagram of infrared absorption based thermal mass flowmeter

▲ Conventional thermal mass flowmeter (with contact, left) and infrared absorption based thermal mass flowmeter (contactless, right)

○ What are its applications?

1. Accurate administration of medication in microflow

In treatments requiring the injection of very small amounts of medication such as drug administration to newborns or special drugs such as anesthetics, accuracy in drug dosage is crucial, and can be a matter of life and death. The contactless flowmeter developed in this study can monitor the flow, enabling accurate administration of drugs in very small doses.

2. Monitoring of semiconductor and chemical processes

This technology can also have industrial applications outside of hospitals. Precise flow control is a crucial part of semiconductor and chemical processes. Using the technology developed in this study to monitor the flow without contact in real time can enhance process efficiency and yield.

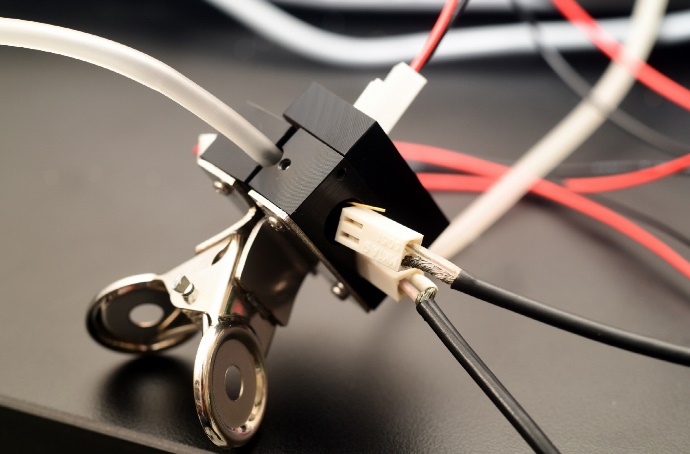

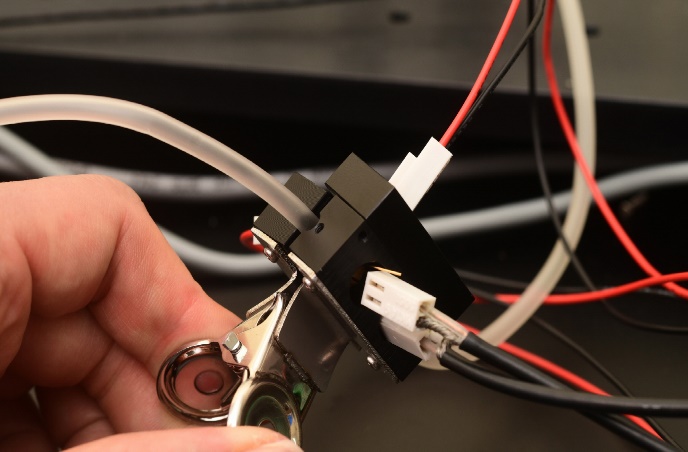

▲ Infrared absorption based thermal mass flowmeter

- Clamp-on mechanism allows flow to be measured when the infusion pump tube is clamped.

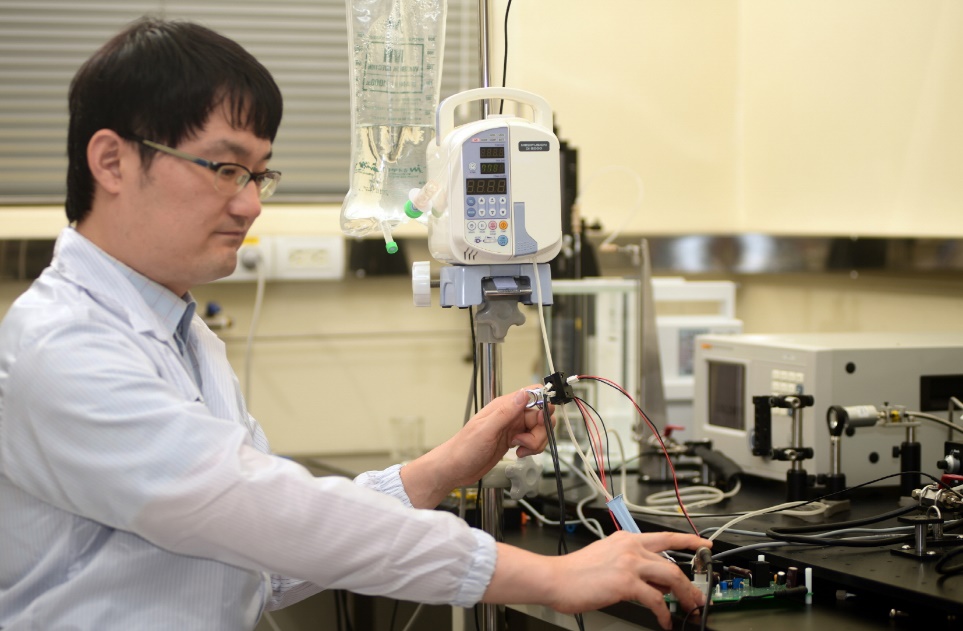

▲ Dr. Seok Hwan Lee, senior research scientist at KRISS Center for Thermometry and Fluid Flow Metrology is measuring the flow of an infusion pump using the thermal mass flowmeter.

QUICK MENU 원하시는 서비스를 클릭하세요!

등록된 퀵메뉴가 없습니다.