Wrinkled Graphene Opens the Door to Various Material Applications

- Writerkrissadmin

- Date2022-07-26 00:00

- Hits505

Wrinkled Graphene Opens the Door to Various Material Applications

- Wrinkled graphene adds stretchability to graphene, a dream material, enabling various material applications -

- The study shows promise for industrial applications such as flexible/wearable devices, solar cells, energy devices, sensors, and filters -

The Korea Research Institute of Standards and Science (KRISS, President Hyun-Min Park) has developed a technique for transferring large-area wrinkled graphene onto polymeric substrates. The transfer of wrinkled graphene was previously limited to specific materials, and the proposed large-area transfer method has broadened the scope of industrial applications.

▲ KRISS researchers, examining the wrinkled graphene structure.

(Left: Seong-Gu Hong, principal researcher / Right: Prashant Narute, doctoral student of UST-KRISS School)

Graphene is called the material of dreams because of its outstanding electrical and thermal conductivity and high durability. When a wrinkled structure is formed, it improves various properties, including stretchability, surface area per volume, optical transmittance, wettability, and electrochemical stability, broadening the scope of applications.

Existing methods for fabricating wrinkled graphene involved the use of elastomers with large elastic deformability, or thermoplastic substrates. The substrates are stretched out, and wrinkles form when they contract back to their original size.

This method is difficult to commercialize since it is almost impossible to separate the wrinkled graphene from substrates. The only solution is to dissolve the substrate using toxic chemicals, but this does not work for elastomers. Moreover, it takes at least two days to dissolve a small piece of thermoplastic film. After this process, the wrinkled graphene is no longer suitable for industrial use because of the presence of residual contaminants and damaged structure.

The KRISS research team developed a method of easily separating wrinkled graphene from substrates without damage, and validated the performance of the separated wrinkled graphene after transfer onto polymeric substrates such as PET and PDMS.

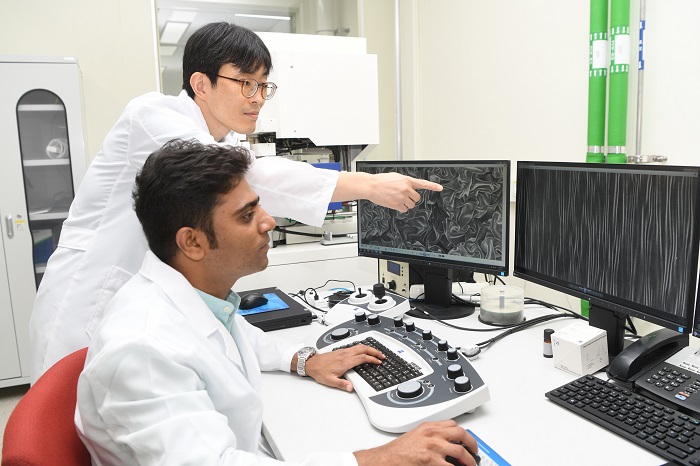

▲ Winkled graphene fabrication and transfer onto PET and PDMS

The key idea of this new technique is to add a water-soluble film between the wrinkled graphene and substrate. After coating the substrate with the water-soluble film, the graphene is transferred by the roll-based process. Strong adhesion forms between the graphene and the substrate, which enables control of the wrinkled graphene structure, even for large areas. To separate the wrinkled graphene from the substrate, the film can then be dissolved using water, for transfer onto other substrates.

Using a water-soluble film, the team transferred wrinkled graphene onto PET and PDMS substrates, and then validated its performance. The wrinkled structure was not damaged on either substrate, and no traces of contaminants were found. The resulting films exhibited outstanding optical transmittance, electrical and mechanical properties, and durability. This is the first-ever attempt to transfer wrinkled graphene onto a PET film, which has small elastic deformability.

The applications of wrinkled graphene include smartphones and wearable devices that require flexible transparent electrodes, sensors and filters with high electrochemical reactivity and efficiency, energy storage devices, and solar cells.

▲ Prashant Narute, doctoral student of UST-KRISS School, shows a sample of wrinkled graphene that was transferred onto a PET substrate.

Seong-Gu Hong, principal researcher of the Interdisciplinary Materials Measurement Institute, said, “By employing the roll-based process, which is commonly used in manufacturing, we made the low-cost, large-area utilization of wrinkled graphene in various applications possible.”

This study, funded by KRISS, was published in the international journal ACS Nano (IF=18.027) in June. Patent applications have been filed for the results in Korea and the United States. The first author is Prashant Narute, a doctoral student of the UST-KRISS School, and the corresponding author is Seong-Gu Hong, a principal researcher.