Breakthrough in Density and Thermal Expansion of Molten Refractory Metals at Ultra-high Temperatures

- Writerkrissadmin

- Date2022-06-29 00:00

- Hits1017

Breakthrough in Density and Thermal Expansion Coefficient Measurements of Molten Refractory Metals at Ultra-high Temperatures

- KRISS develops high-precision measurement technology for thermal properties of materials that withstand temperatures over 3,000 K -

- Expected to enhance new materials development and safety and efficiency of major industries exposed to extreme conditions, such as aerospace, aviation, national defense, and energy -

Korea Research Institute of Standards and Science (KRISS, President Hyun-Min Park) developed high-precision technology to measure the thermal properties of molten refractory metals in ultra-high temperature environments over 3,000 K*, by using electrostatic levitator.

* K (Kelvin): Unit of temperature. 3,000 K is equivalent to 2,727 °C. In general, the temperature of a furnace in a steel mill is 1,773 K, and the surface temperature of the sun is 6,000 K.

▲ KRISS Frontier of Extreme Physics Team

(From left: Le Huu Nhat, UST student researcher; Yong Chan Cho, senior researcher; Sangho Jeon, post-doc researcher; Joohyun Lee, principal researcher)

On June 21, Korea succeeded in the test launch of the Nuri rocket, propelled through fuel combustion reaching a temperature as high as 3,773 K. Even with a cooling device, the metal alloys used in launch vehicles must be able to withstand high temperatures above 3,000 K.

Heat-resistant metals such as titanium and tungsten are commonly used in space launch vehicles, aircraft engines, and nuclear fusion reactors. Their efficiency improves with operating temperature, but for design stability, it is essential to accurately determine their thermal properties as metals expand in volume at high temperatures.

Commercially available instruments used to measure thermal properties rely on the traditional contact method, and support temperatures up to 2,000 K. Since high temperature environment causes unwanted contamination and reaction with surroundings with the traditional contact methods, non-contact methods, such as levitation techniques, should be required for samples under higher temperature condition. Electrostatic levitator (ESL) can provide a way measuring the high temperature thermophysical properties. ESL is owned by leading countries in the aerospace sector, such as the United States, Germany, China, Japan, and Korea.

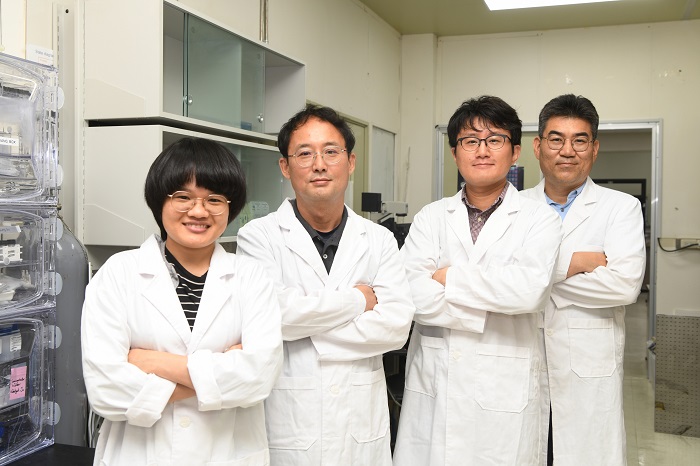

▲ Main cause of inconsistency in thermal property measurements over 3,000 K based on the KRISS research team’s findings

While thermal property measurements using an electrostatic levitator have been relatively consistent for temperatures below 2,000 K, they are less reliable at higher temperatures with largely scattered data.

The KRISS Frontier of Extreme Physics Team identified the cause of inconsistency in past research based on measurements of thermal properties above 3,000 K, and developed a method of obtaining precise, reliable measurements. The team is the first in the world to conduct high-precision analysis on uncertainties related to thermal property measurements over 3,000 K.

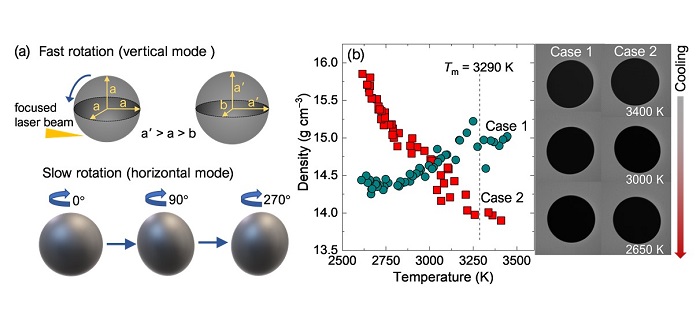

▲ The KRISS Frontier of Extreme Physics Team is measuring the thermal properties of heat-resistant metals under ultra-high temperatures using an electrostatic levitator.

(From left: Joohyun Lee, principal researcher; Yong Chan Cho, senior researcher)

The team levitated samples of niobium (2750 K), molybdenum (2896 K), and tantalum (3290 K) using an electrostatic levitator, and melted them with high-output lasers. They succeeded in repeatedly obtaining precise measurements of liquid density and thermal expansion at temperatures over 3,000 K.

The results provide reference values not only for alloys used in space launch vehicles, aircraft engines, and gas turbines of nuclear reactors, but also enhance the safety and efficiency of metal 3D printing processes.

Geun Woo Lee, principal researcher of KRISS, said, “It was essential to secure novel technology at the national level for aerospace, aviation and defense industries, which have mostly relied on imports. Our results will help raise the standards of local industries that are exposed to extreme conditions.”

KRISS will conduct follow-up research at higher temperatures up to 4,000 K, and based on the findings, develop heat-resistant materials for use in extreme conditions.

Supported by KRISS, the research was approved for online publication in the June issue of Metrologia (IF: 3.157), a prestigious journal in measurement standards.