Improving Performance of Next-Generation Lithium Ion Battery- Nanotunnel Has the Solution

- Writerkrissadmin

- Date2021-12-29 00:00

- Hits1132

Improving Performance of Next-Generation Lithium Ion Battery-

Nanotunnel Has the Solution

- KRISS-Konkuk University joint research team developed a material for lithium ion battery

to drastically improve the initial Coulombic efficiency and capacity by using iron oxide. -

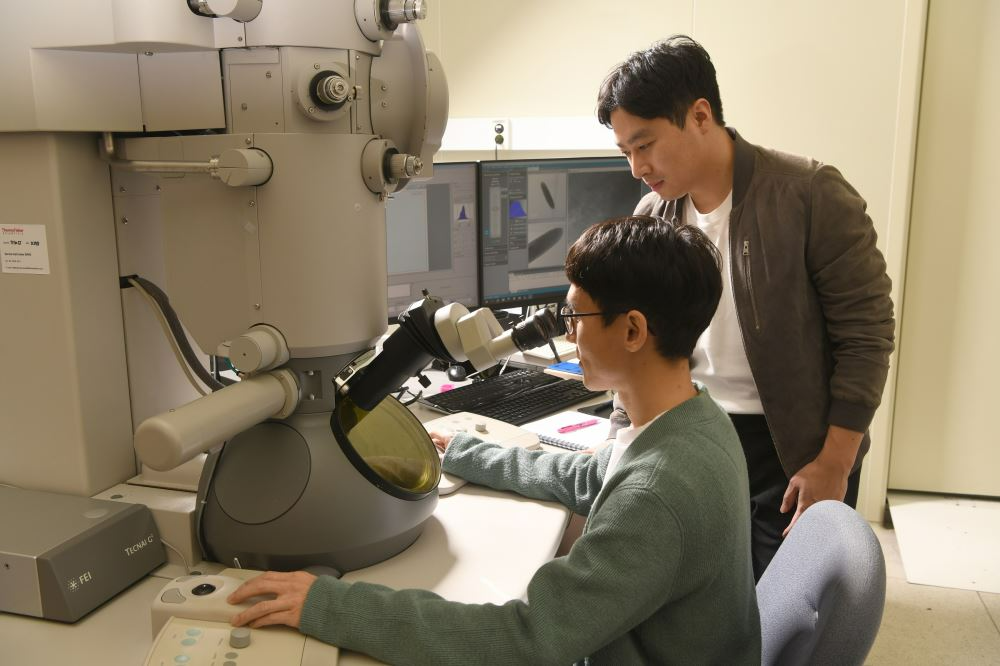

▲ Ji-Hwan Kwon, a senior research scientist of the Interdisciplinary Materials Measurement Institute at KRISS (left),

and Professor Yeonho Kim at Konkuk University (right) are measuring the properties of the developed material.

The EM Nanometrology Team of the Interdisciplinary Materials Measurement Institute at KRISS conducted a joint study with Professor Yeonho Kim’s group at Konkuk University developed an iron oxide nanostructure for drastically improving the initial Coulombic efficiency* and capacity of lithium ion battery.

*Coulombic efficiency: The ratio of the total charge from a battery after the latest charge cycle to the total charge from the battery after the previous charge cycle.

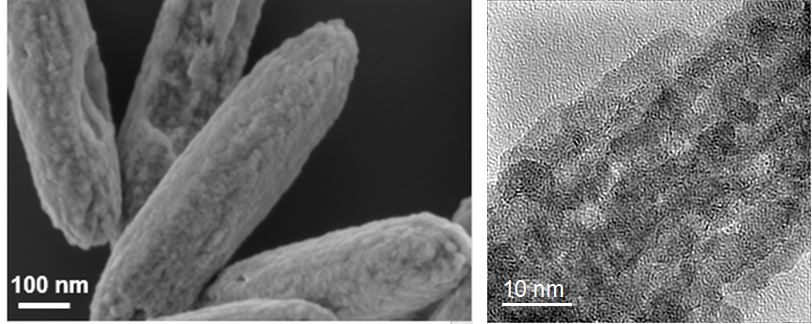

The feature of the material developed in this study is that the internal pores are linearly arranged in the shape of nanotunnel. The initial Coulombic efficiency is about 85.4%, which is highest among the iron oxides that have been published by now. The newly developed material can be applied as a next-generation negative electrode material to significantly improve the performance of secondary battery.

Lithium ion battery have already been applied broadly to various fields, including small electronic devices, IT devices and electric vehicles. The demand is rapidly increasing for next-generation battery that can be charged faster, that works longer, that is lighter and that has a higher power density. Since the future energy materials should have not only improved characteristics but also environment-friendliness, R&D works are performed on such materials that can satisfy the conditions.

Iron oxide has been much studied as a material for lithium ion battery, since it is abundant on our planet and has low toxicity and high chemical stability. Oxides of transition metals, including iron oxide, can use a great number of lithium ions in charging and discharging, and so they can provide three or four times higher capacity, compared with the conventional graphite materials.

Despite these advantages, the actual applications of iron oxide have been limited due to the low lithium mobility, large volume change, and low initial Coulombic efficiency. The KRISS-Konkuk University joint research team successfully developed a method for overcoming the low Coulombic efficiency, a disadvantage of the existing iron oxide-based lithium ion battery.

To improve the mobility of lithium ion in iron oxide, the joint research team prepared a material in a mesoporous shape. In addition, to enhance the lithium mobility inside the iron oxide, the pores were linearly arranged in the shape of nanotunnel. Since the tunnels and the many pores on the surface allow the lithium ions to migrate easily, the material has electrochemical properties that are much better than those of the conventional lithium ion materials.

▲ Schematic illustration of the inside of the lithium ion battery

developed by the KRISS-Konkuk University joint research team

The joint research team carefully analyzed the microstructure of the material depending on the charging and discharging of the lithium ion battery by using TEM and the Pohang Accelerator (1C PAL-KRISS beam line), and found that a particular structure formed in the initial charge/discharge process plays a critical role in the electrochemical reactions.

Ji-Hwan Kwon, a senior research scientist of the Interdisciplinary Materials Measurement Institute at KRISS, commented, “Our results not only addressed the drawbacks of the existing materials and improved the battery capacity but also found the reason and basis of the good properties exhibited by the newly developed material.” He added, “We are looking forward to applying these results to develop various kinds of lithium ion battery materials, further activating the next-generation battery market.”

The study was supported by the Key Research Program of KRISS. The results of the study were published as a supplementary cover article in ACS Sustainable Chemistry & Engineering (IF: 8.198), a globally acclaimed journal, in December.